The neodymium magnet assembly assures high flux concentration, low power compression and excellent heat exchange, since the external magnet configuration is considerably more efficient than traditional under-pole magnet topology. This results in high levels of force factor and power handling with an optimum power to weight ratio. The direct contact between the large heat sink and basket, together with the magnetic structure, represent a fundamental improvement in thermal connection and heat dissipation. Hence, power handling capabilities are increased and power compression lowered. The deep profile curvilinear cone, created from a special high strength wood pulp, has been designed to achieve the best possible linearity within its frequency range. The cone surround, made from a linen material is highly resistant to aging and fatigue. The in-house developed cone treatment is a humidity repellent and significantly dampens bell mode resonances. The 75mm (3in) copper

EDGE-wound voice coil assembly is wound on a strong fiberglas former to improve force transmission and power handling. The already low distortion and sound quality are further improved by Double Demodulating Rings (DDR) that flatten impedance and phase with a constant power transfer. A special coating applied to both the top and back plates makes the 15ND930 far more resistant to the corrosive effects of salts and oxidization.

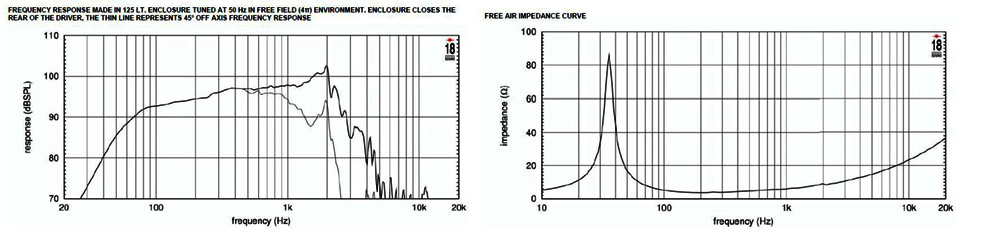

Driver diagram

Driver chart

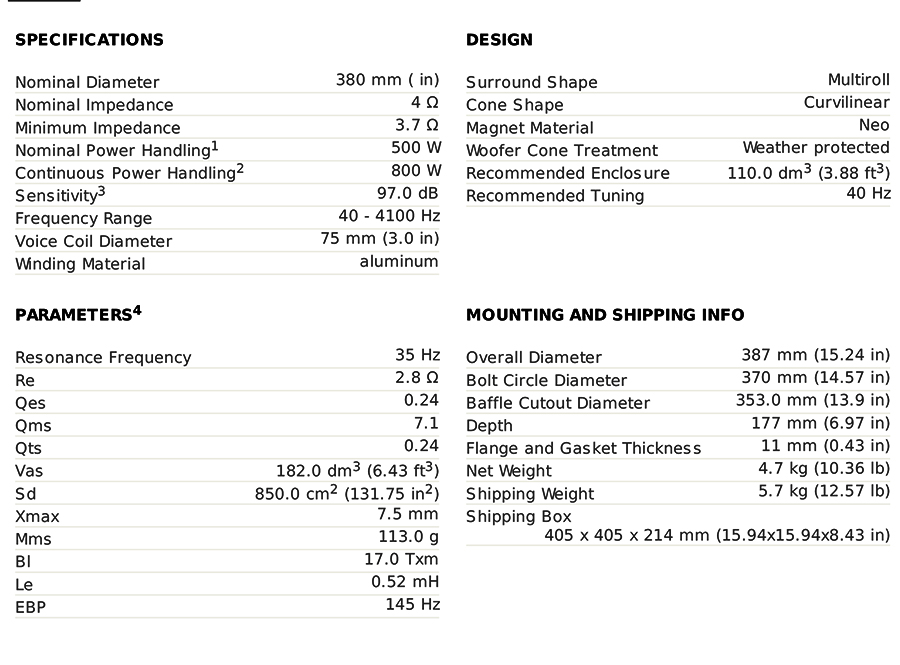

Specifications

1. 2 hours test made with continuous pink noise signal within the range Fs-10Fs. Power calculated on rated minimum impedance. Loudspeaker in free air.

2. Power on Continuous Program is defined as 3 dB greater than the Nominal rating.

3. Applied RMS Voltage is set to 2.83 V for 8 ohms Nominal Impedance.

4. Hight- pass filter 12 dB/oct